![]()

Adr :industrial zone, shanghai

Phone : +86 18221614363

Email : candymachinery@qq.com

Tel : +86 18221614363

processing capacity:150-1200kg/H

Application scope:lollipop candy

Product introduction: Automatic Die-formed lollipop candy production line can produce all kinds of lollipop, solid lollipop Candy, filled lollipop Candy, shaped lollipop Candy, color lollipop Candy

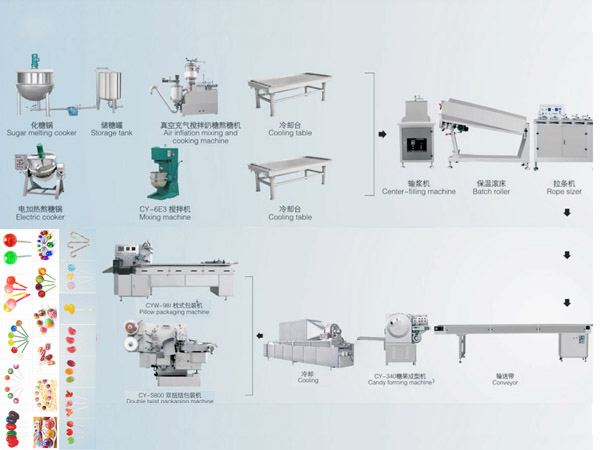

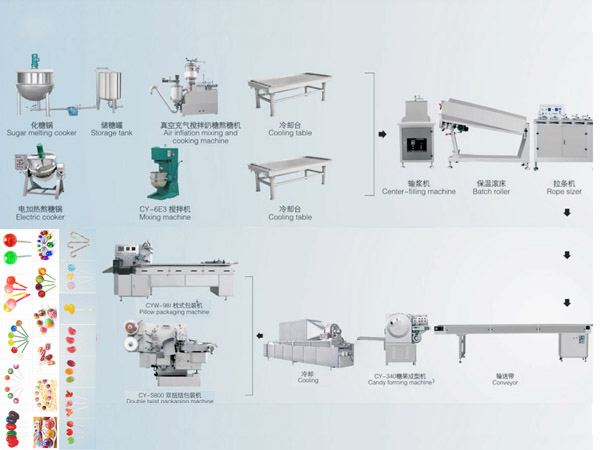

Die forming lollipop making equipment

Lollipop making equipment is mainly composed of sugar melting pot, pump, storage barrel, vacuum continuous sugar boiling machine, cooling platform, thermal insulation roll bed, equalizing machine, ball candy forming machine, distribution machine, conveyor belt, refrigerator. The production line has compact structure and stable performance. The lollipop is molded with automatic rod insertion function. After forming, the individual lollipop is full, which is transported to the cooling conveyor belt by the distributing machine and into the freezer. In the conveying process, the candy deformation is small and the surface is smooth.

Scope of application: Suitable for the production of all kinds of spherical, oblate, oval and a variety of special shape lollipop.

Automatic Die-formed lollipop making equipment can produce all kinds of lollipop Candy, solid lollipop Candy, filled lollipop Candy, shaped lollipop Candy, color lollipop Candy and other lollipop Candy

Continuously vacuum cooker, guarantee the quality of sugar masses.

Special forming style is better for central-filling.

Production capacity can be from 50 to 1200kg/h.

Sanitary structure designed.

The central filler, rope sizer and former work together available.

Different lollipop shape can be made depend upon changing of the mould.

A better effect of cooling is available by the conveying and cooling system.

Lollipop can be made when the lollipop former is set instead of lollipop Candy former.

Machine characteristics

The heating time, heating temperature, depositing time and depositing speed are all computer controlled.

The production line is equipped with a 10.7-inch touch screen for an easy and clear display of different parameters, including the flow chart, part status, temperature, depositing speed and other parameters.

Syrup flow is precisely controlled via a frequency control system to ensure a stable sugar paste quality.

By changing molds and device components, this production line is used in the production of suckers in a variety of shapes, including spherical, flat, and 3D.

It is easy to operate and maintain.

The production line can be customized to fit your site conditions.

Technological process of Die forming toffee production line

Sugar melting cooker-Storage tank-Vacuum sugar cooking machine-Cooling table-Center filling machine-Batch roller-Rope sizer-lollipop forming machine-Cooling sifter-packaging machine

Main machine of die forming lollipop making equipment

Toffee boiling machine

The sugar boiling pot is specially designed and manufactured for the production of charred sweet. The heating method is steam jacket heating, and the internal scraping and stirring effectively prevent the sugar paste from coking during the boiling process. This machine can cook toffee, caramel, and other candies.

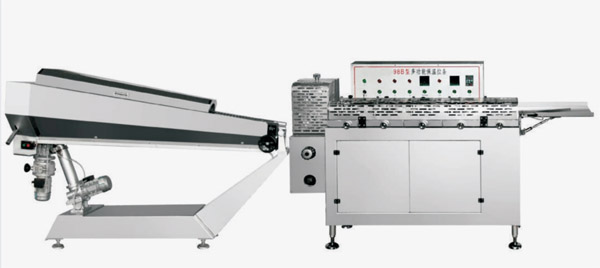

Insulation roller bed drawing machine

Purpose and characteristics:

It is suitable for heat preservation and stretching of sugar paste.

Simple operation, labor saving and high efficiency.

Technical parameters:

Maximum capacity of roller bed: 0.18m ³

Stripping speed: ≤ 25m/min

Total power: 6.3kw

Machine weight: 720kg

Multi-functional lollipop forming machine

It is applicable to the production of lollipop ,also can be used for the production of crispy candy (the shape of sugar can be determined according to customer requirements), such as spherical, oblate, oval and many kinds of abnormity.

characteristic of Multi-functional candy forming machine

Stamping, smooth operation and high output.

technical parameter

Production capacity: w250kg/h

Total power: 2.4kw

Weight: 800kg

All rights reserved:ZHI YAN CANDY MACHINERY Co.,Ltd SitemapSitemap Candy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production line