![]()

Adr :industrial zone, shanghai

Phone : +86 18221614363

Email : candymachinery@qq.com

Tel : +86 18221614363

processing capacity:50-1200kg/h

Application scope:lollipop candy

Product introduction: The Depositing lollipop candy production line a continuous vacuum thin film lollipop making machine. The equipment integrates mechanical, electrical and control systems, which is easy to operate, compact in structure and automation

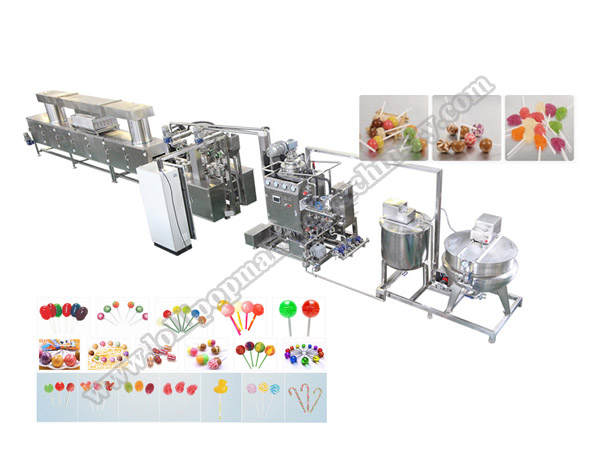

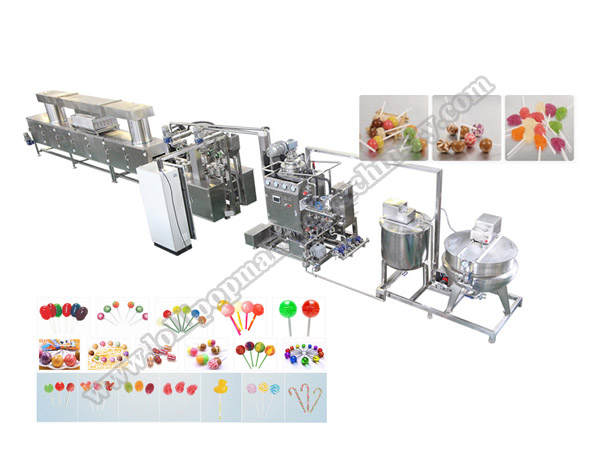

Depositing lollipop making machine

This lollipop making machine is designed base on the candy depositing line. With more than 20 years candy depositor fabricating experience,the 4th generation lollipop making machine is developed base on the 3rd generation machine.lt is an advanced equipment which can continuously produce various kinds of lollipop under a strict sanitary condition.

The whole line is produced according to the GMP standa rd of food machinery; it is not only an ideal equipment which can produce out good quality products with the saving of both the manpower and the space occupied, but also help the candy manufacturer pass the GMP, HACCP, QS authentication easily.

The Depositing lollipop making machine a continuous vacuum thin film lollipop making machine. The equipment integrates mechanical, electrical and control systems, which is easy to operate, compact in structure and automation. The continuous vacuum film Depositing making machine can not only produce transparent crystal sugar, two-color sugar, double-layer double-flavor sugar, sandwich sugar, but also produce colorful and multi-flavor candy such as spiral spray candy.

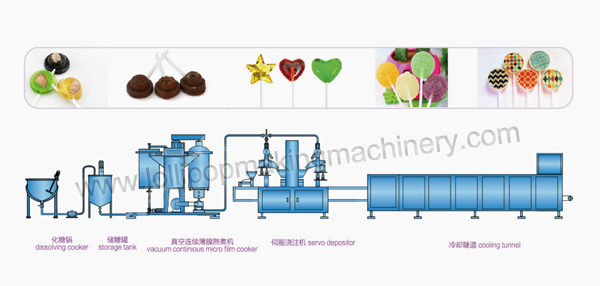

Process flow of Depositing lollipop making machine

Dissolving sugar - conveying - filtering - temporary storage - quantitative conveying of syrup - preheating film vacuum boiling, unloading, online mixing of essence and pigment syrup - content - Depositing - cooling - demoulding - conveying - packaging - finished product

advantage of Depositing lollipop candy making machine

Computer control vacuum sugar boiling temperature, time, Depositing temperature and Depositing speed

10.7-inch touch screen displays process flow diagram, working status of each part, temperature, Depositing speed and other parameters

The accurate flow of sugar liquid is controlled by frequency conversion and speed regulation, and the quality of sugar paste is stable

Various shapes of candy can be produced according to different molds

Replace some devices and molds, the making machine can produce spherical and flat three-dimensional lollipops

Easy to operate and maintain

Non-standard machines can be determined according to customers' site requirements

Main machine of depositing lollipop making machine

Jacketed cooking kettle

The jacketed cooking kettle is used to dissolve and cook ingredients such as glucose, granulated sugar, and water. It uses electric heating and features a large heating area, heating uniformity, and easy to control the temperature. This equipment improves product quality and shortens the processing time.

lollipop depositor machine

The depositing machine uses PLC to control the parameters such as temperature and depositing speed. These parameters are easy to read and set on the touch screen, while the syrup flow is precisely controlled via a frequency control system to ensure a stable sugar paste quality.

lollipop candy mold

The lollipop production line manufactures candies in a variety of shapes using different molds. We will design molds according to your needs.

lollipop candy cooling tunnel is designed to match the high production of candy forming line. This equipment provides rapid cooling for large volumes of formed lollipop candy with optimum distribution of the lollipop candy on the cooling line. Through the cooling unit and cycle transport system, the product won't be cracking, deformation, lapping or conglutination on the cooling line. It is optimum equipment of cooling large volume of candy.

Depositing lollipop candy making Machine Working Principle

Primary components of lollipop candy depositing machine: conveyor belt, model plate, syrup nozzle, syrup depositing pump, storage tank, cooling device. Casting mold molding can produce lollipop candy, do gummy candy and gummy candy, its wide range of adaptation, the need for roughly the same equipment. When the boiled sugar paste is still in the active state, the liquid sugar paste is injected into the continuous running model plate, and then it is rapidly cooled and shaped, and then separated from the model plate, and then sent to the packaging machine with the conveyor belt for packaging.

Model:ZY1200B-S-lollipop making machine

Capacity:1200kg/h

Candy weight:According to the size of candy

Depositing Speed:30-60n/min

Steam requirement:1200kg/h,0.5-0.8MPa

Compressed air requirement:0.6m³/min,0.4-0.6MPa

Working condition:Temperature 20-25°C;Humidity 45-55%

Electric power needed:56kw/380v

Total Length:40m

Weight of machine:12000kg

Model:ZY600B-S-lollipop making machine

Capacity:600kg/h

Candy weight:According to the size of candy

Depositing Speed:25-35n/min

Steam requirement:500kg/h,0.5-0.8MPa

Compressed air requirement:0.3m³/min,0.4-0.6MPa

Working condition:Temperature 20-25°C;Humidity 45-55%

Electric power needed:38kw/380v

Total Length:22m

Weight of machine:7000kg

Model:ZY450B-S-lollipop making machine

Capacity:450kg/h

Candy weight:According to the size of candy

Depositing Speed:25-35n/min

Steam requirement:400kg/h,0.5-0.8MPa

Compressed air requirement:0.25m³/min,0.4-0.6MPa

Working condition:Temperature 20-25°C;Humidity 45-55%

Electric power needed:34kw/380v

Total Length:19m

Weight of machine:6000kg

Model:ZY300B-S-lollipop making machine

Capacity:300kg/h

Candy weight:According to the size of candy

Depositing Speed:25-35n/min

Steam requirement:300kg/h,0.5-0.8MPa

Compressed air requirement:0.2m³/min,0.4-0.6MPa

Working condition:Temperature 20-25°C;Humidity 45-55%

Electric power needed:27kw/380v

Total Length:19m

Weight of machine:5000kg

Model:ZY150B-S-lollipop making machine

Capacity:150kg/h

Candy weight:According to the size of candy

Depositing Speed:25-35n/min

Steam requirement:250kg/h,0.5-0.8MPa

Compressed air requirement:0.2m³/min,0.4-0.6MPa

Working condition:Temperature 20-25°C;Humidity 45-55%

Electric power needed:18kw/380v

Total Length:17m

Weight of machine:4000kg

All rights reserved:ZHI YAN CANDY MACHINERY Co.,Ltd SitemapSitemap Candy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production line