![]()

Adr :industrial zone, shanghai

Phone : +86 18221614363

Email : candymachinery@qq.com

Tel : +86 18221614363

processing capacity:50-1200KG/H

Application scope:lollipop candy

Product introduction:

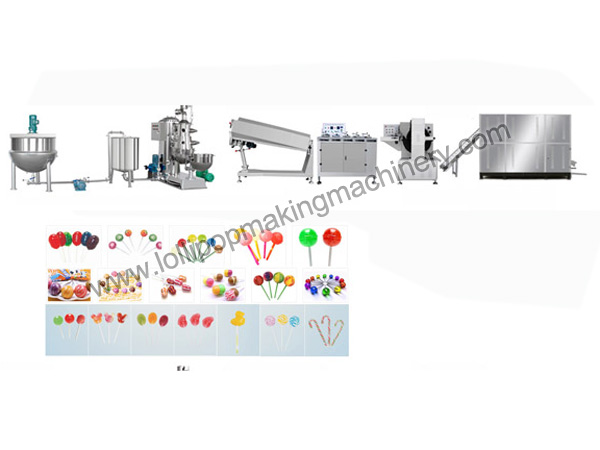

Automatic Die-formed lollipop Production Line can produce all kinds of lollipop, solid lollipop, filled lollipop, shaped lollipop, color lollipop and other lollipop

Die-formed lollipop Candy Production Line

The die-formed lollipop production line produces lollipop in a variety of shapes through the use of different molds. It is ideal for candy factories planning to mass produce different lollipop candy shapes and features a maximum capacity of 50-1200kg.hour. die-formed lollipop making machine is equipped with an electric heating cooker to ensure an even PLC controlled heating time and temperature, ensuring the lollipop is transparent and features a good taste. This advanced lollipop making equipment effectively reduces material waste. Backed by extensive experience, not only do we offer customized die-formed lollipop production lines, but we also offer the matched molds.

Automatic Die-formed lollipop Candy Production Line can produce all kinds of lollipop Candy, solid lollipop Candy, filled lollipop Candy, shaped lollipop Candy, color lollipop Candy and other lollipop Candy

Automatic lollipop Candy die-forming production line is composed of automatic weighing and batching system, vacuum sugar boiling machine, cooling steel belt conveyor, conveyor belt, thermal insulation rolling machine, strip equalizing machine, lollipop Candy die-forming and forming machine, cooling tunnel, etc. High yield, automatic control, less water content of syrup, continuous cooling, continuous molding, molding speed, less sugar residue, simple operation, convenient cleaning. It is an ideal sandwich or no sandwich lollipop Candy die-forming line.

Continuously vacuum cooker, guarantee the quality of sugar masses.

Special forming style is better for central-filling.

Production capacity can be from 50 to 1200kg/h.

Sanitary structure designed.

The central filler, rope sizer and former work together available.

Different candy shape can be made depend upon changing of the mould.

A better effect of cooling is available by the conveying and cooling system.

Lollipop can be made when the lollipop former is set instead of lollipop Candy former.

Technological process of Die-formed lollipop Candy Production Line

Sugar melting cooker-Storage tank-Vacuum sugar cooking machine-Cooling table-Center filling machine-Batch roller-Rope sizer-Candy forming machine-Cooling sifter-packaging machine

Main component equipment of Die-formed lollipop Candy Production Line

Vacuum sugar cooking machine

It features automatic temperature control, high output, time-saving, short cooking time, and can manufacture the syrup with high transparency.

①.Sugar melting cooker

Batch size(L):300

Weight(kg):280

Dimension(mm):1100*1100*1700

②.Storage tank

Batch size(L):300

Weight(kg):220

Dimension(mm):740*740*1250

③. Technical parameters

Production capacity(kg/h):350-400

Heating area(m³):2.45

Steam pressure(MPa):0.7-1.0

Syrup temperature before entering(°C):110-115

Temperature after discharging(°C):135-145

Power- Fixed displacement pump(kw):0.75

Power- Vacuum pump(kw):5.5

Machine weight(kg):800

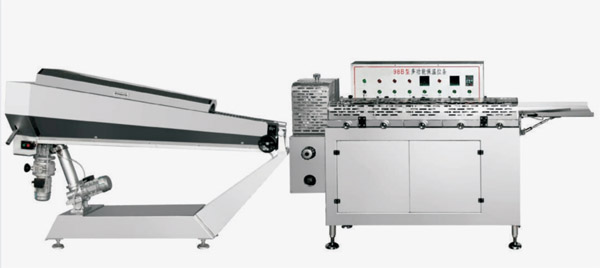

Heat preservation batch roller and rope sizer

Purpose

It is suitable for heat insulation and pulling of sugar pastes.

Feature

It has such features as simple operation, labor saving and high efficiency.

Technical parameters

Batch roller maximum capacity(m³):0.20

Running speed(m/min):≤40

Weight(kg):850

Dimension(mm):(Five-wheel):4525*890*1700

Multi function lollipop forming machine

Purpose。

It is suitable for production of lollipop , gaining creamy candy, toffees and filled candy, as well as production of cushions (candy shapes varying according to customer requirements), such as: spherical, oblate, oval and other irregular shapes.

Feature

Punching and forming, stable running, high output

Technical parameters

Total power: 2.4kw

Weight: 800kg

Dimension: 2000 x 1100 x1300mm

Candy cooling tunnel

Candy cooling tunnel is a fast cooling equipment designed to cooperate with high yield candy forming production line such as high-speed stamping forming machine, etc. The equipment can provide ideal cooling distribution for large quantities of candy in the cooling tunnel. Through the circulation cooperation of the cooling unit and conveying system, the candy will not be split, deformation, overlap, adhesion and other phenomena in the rapid cooling process. Is ideal for high volume candy cooling equipment.

All rights reserved:ZHI YAN CANDY MACHINERY Co.,Ltd SitemapSitemap Candy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production line