![]()

Adr :industrial zone, shanghai

Phone : +86 18221614363

Email : candymachinery@qq.com

Tel : +86 18221614363

processing capacity:50-2000kg/H

Application scope:lollipop candy

Product introduction: Full-automatic depositing lollipop production line can lollipop candy, and can be made into single color, sandwich double color, left and right double color, up and down double color lollipop candy.

Lollipop Production Line

Automatic depositing lollipop production line

Automatic lollipop depositing production line is mainly used for lollipop making. It integrates mechanical, electric, compressed air, and automatic control. feature is its high capacity, high quality, various product design, easy operation, reliable

structure design, and high automatic grade. It can not only produce single color lollipop, double colors lollipop, center filled lollipop, but also double balls lollipop product by depositing system increased

The PLC control system is adopted in the full-automatic production line for depositing lollipop making machine. lollipop making machine is developed by the R&D Department of our company according to the market demand for gel lollipop candy in various shapes and colors and the production process adopted. It is an ideal equipment for continuous production of high-grade candy (sugar). It can produce high-quality single-color and two-color sugar; High quality and various shapes can also be produced by changing the mold or depositing head. Gel jelly of many colors. Complete the quantitative injection and mixing of essence pigment acid online; Highly automated production can not only produce products with stable quality, but also save manpower and space to reduce production capital.

The fully automatic depositing lollipop candy production line is made of stainless steel 304 and 316 materials, which meet the requirements of health care products, food and drug hygiene, and reaches the waterproof GMP 35 grade. The complete machine is sandblasted, and the equipment operating surface is all arc-shaped chamfered to protect the safety of operators!

Full-automatic depositing lollipop making machine can lollipop candy, and can be made into single color, sandwich double color, left and right double color, up and down double color lollipop candy.

Product features

1. With famous PLC and servo depositing, the original depositing system has more stable performance,

2. Automatic control of vacuum sugar boiling temperature, time, holding temperature and depositing speed by programming;

3. Siemens large touch screen displays the process flow chart, the working status of each part, the setting and display of parameters such as temperature and depositing speed, which makes it easier for users to operate and master;

4. The production capacity of series products can range from 50 kg to 2000 kg per hour;

5. The accurate flow of sugar liquid is controlled by frequency conversion and speed regulation, and the quality of sugar paste is stable;

6. The servo motor controls the size of the candy, and can replace the distribution board to make multi-color and other sandwich lollipop candy;

7. The dynamic mixer completes the quantitative filling and mixing of essence, pigment and acid liquid online;

8. Conveying chain belt, cooling system and double demoulding mechanism ensure demoulding;

9. Various shapes of candy can be produced according to different molds;

10. Optional quantitative filling system can produce sandwich candy;

11. Replacement of customized parts of boiling and devices and molds can produce lollipop candy, hard candy, spherical lollipop, flat lollipop, etc.

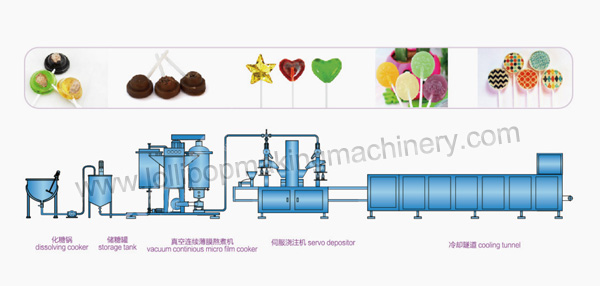

Automatic depositing lollipop production line process flow

Raw material dissolving^Transporting->Storage->Dosing —Preheating — Micro-film cooking Discharging -> Mixing with flavor and color -> Depositing -> Cooling — De moulding — Conveying-> Packing

Main machine of Automatic depositing lollipop production line

Continuous vacuum cooker

Main components: syrup pump, heater, syrup inlet, secondary steam discharge system, needle valve, vacuum steam chamber, discharge control system, rotary pot, vacuum system.

The jacketed cooking kettle is used to dissolve and cook ingredients such as glucose, granulated sugar, and water. It uses electric heating and features a large heating area, heating uniformity, and easy to control the temperature. This equipment improves product quality and shortens the processing time.

The depositing machine is composed of the depositing head, mold, and refrigerated cooler. The depositing head is equipped with double hopper and by replacing the stamping board and nozzle, this equipment is used for the production of filled suckers and two-color suckers. It uses PLC to control different parameters, such as temperature and depositing speed. These parameters are easily set and displayed on the touch screen. Syrup flow is also precisely controlled using a frequency control system to ensure sugar paste quality.

Gummy mold

The gummy mold is customized according to the gummy shape required by the customer. The material of the mold is steel mold and silicone mold. Different materials of the mold can be selected according to the customer's intention

Candy Cooling Tunnel

Power :25kw-50kw(depends cooling unit)

Voltage :380,50hz

Cooling time :8-15min

Water consumption :4m3/h

Running condition(temperature) :5-35℃

Running condition(humidity) :30%-60%

Size(L*W*H) :7M*1.32M*2.61M

Weight :3000kgs

gummy candy cooling tunnel is designed to match the high production of candy forming line. This equipment provides rapid cooling for large volumes of formed gummy candy with optimum distribution of the gummy candy on the cooling line. Through the cooling unit and cycle transport system, the product won't be cracking, deformation, lapping or conglutination on the cooling line. It is optimum equipment of cooling large volume of candy.

The model of the lollipop production line

The model of the lollipop production line

Model:ZY2000-lollipop production line

Capacity:2000kg/h

Candy weight:According to the size of candy

Depositing Speed:55-65n/min

Steam requirement:650kg/h,0.5-0.8MPa

Compressed air requirement:0.45m³/min,0.4-0.6MPa

Working condition: Temperature 20-25°C;Humidity 45-55%

Electric power needed:60kw/380v

Total Length:30m

Weight of machine:10500kg

Model:ZY1200-lollipop production line

Capacity:1200kg/h

Candy weight:According to the size of candy

Depositing Speed:55-65n/min

Steam requirement:650kg/h,0.5-0.8MPa

Compressed air requirement:0.45m³/min,0.4-0.6MPa

Working condition: Temperature 20-25°C;Humidity 45-55%

Electric power needed:48kw/380v

Total Length:22m

Weight of machine:7500kg

Model:ZY600-lollipop production line

Capacity:600kg/h

Candy weight:According to the size of candy

Depositing Speed:55-65n/min

Steam requirement:500kg/h,0.5-0.8MPa

Compressed air requirement:0.3m³/min,0.4-0.6MPa

Working condition: Temperature 20-25°C;Humidity 45-55%

Electric power needed:40kw/380v

Total Length:20m

Weight of machine:5000kg

Model:ZY450-lollipop making machine

Capacity:450kg/h

Candy weight:According to the size of candy

Depositing Speed:55-65n/min

Steam requirement:400kg/h,0.5-0.8MPa

Compressed air requirement:0.25m³/min,0.4-0.6MPa

Working condition: Temperature 20-25°C;Humidity 45-55%

Electric power needed:34kw/380v

Total Length:17m

Weight of machine:4500kg

Model:ZY300-lollipop making machine

Capacity:300kg/h

Candy weight:According to the size of candy

Depositing Speed:55-65n/min

Steam requirement:300kg/h,0.5-0.8MPa

Compressed air requirement:0.2m³/min,0.4-0.6MPa

Working condition: Temperature 20-25°C;Humidity 45-55%

Electric power needed:27kw/380v

Total Length:17m

Weight of machine:4000kg

Model:ZY150-gummy making machine

Capacity:150kg/h

Candy weight:According to the size of candy

Depositing Speed:55-65n/min

Steam requirement:250kg/h,0.5-0.8MPa

Compressed air requirement:0.2m³/min,0.4-0.6MPa

Working condition: Temperature 20-25°C;Humidity 45-55%

Electric power needed:18kw/380v

Total Length:15m

Weight of machine:3500kg

All rights reserved:ZHI YAN CANDY MACHINERY Co.,Ltd SitemapSitemap Candy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production line